Are you finding your backyard space a bit cramped, maybe even overflowing with garden tools, bikes, or outdoor gear? It's a common story, you know, and finding a smart spot for everything can feel like a big puzzle. Well, a lean-to shed could be just the answer you're looking for, offering a neat and tidy home for all those items that need a place. These handy structures are pretty popular, too, because they attach right onto an existing building, saving space and often materials. It’s a project that many folks find quite rewarding, and it can really make a difference in how organized your outdoor area feels, almost instantly.

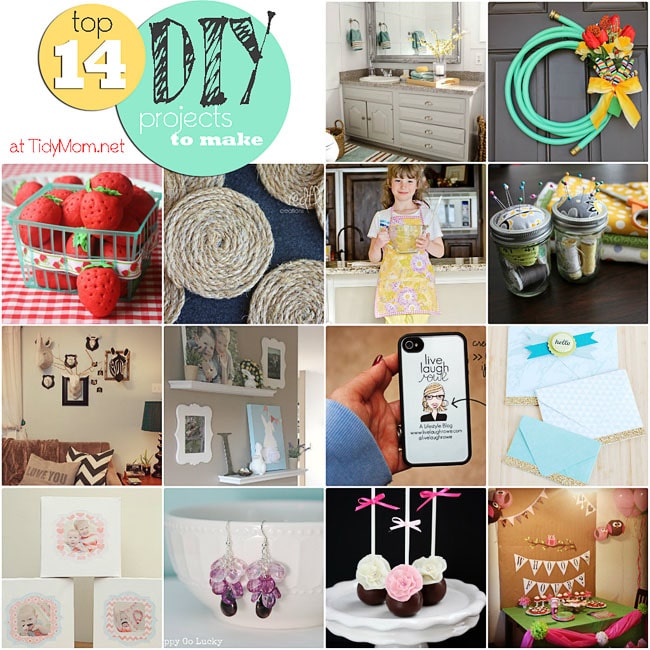

Getting into DIY projects, like building your own lean-to shed, is a fantastic way to tackle those home improvement needs without breaking the bank. You see, there are thousands of free DIY projects out there, and building a shed fits right in with that spirit of making things yourself. It’s about taking on something new, learning as you go, and then having something really useful to show for your effort. This kind of project, in a way, embodies the idea that small updates can truly make a big impact on your home, both inside and out.

This guide is here to walk you through everything you might want to know about building your own lean-to shed, from finding the right plans to putting the pieces together. We'll explore why these sheds are such a great choice for many homeowners and how you can get started, even if you’re just beginning your DIY journey. So, if you've been curious about what DIY projects you can take on, or if you're looking for a functional fix that also enhances your space, building a lean-to shed is definitely worth considering. It's a very practical way to organize and maintain your space, and it can be a pretty fun project, too, to be honest.

Table of Contents

- Why a DIY Lean-To Shed is a Smart Choice

- Getting Started with Your Lean-To Shed Project

- Step-by-Step Building Basics

- Common Questions About DIY Lean-To Sheds

Why a DIY Lean-To Shed is a Smart Choice

When you think about adding storage to your property, a lean-to shed often comes up as a top contender, and for some very good reasons. They are, in a way, the clever cousins of freestanding sheds, offering a lot of utility with a smaller footprint. This makes them especially appealing for homes where every bit of outdoor area counts. Plus, taking on a project like this yourself can be incredibly satisfying, giving you a real sense of accomplishment, you know?

Space-Saving and Efficiency

One of the biggest perks of a lean-to shed is how little space it actually needs. Because it leans against an existing structure, like your house or garage, it doesn't need four independent walls. This saves on materials, yes, but also means it tucks neatly into spots that a traditional shed might not fit. It's a pretty efficient use of space, actually, allowing you to maximize your yard without feeling like it's taken over by a big building. You can find small lean-to shed designs that fit almost anywhere.

This design also often means less material is needed for the back wall, which can attach directly to your home's siding. That’s a pretty neat trick for saving wood and other building supplies. It's a smart choice for anyone looking to add functional storage without sacrificing precious yard space. So, if you're tight on room, this type of shed really shines, offering a compact solution.

Cost-Effective Solutions

Building something yourself, especially a structure like a shed, typically costs less than buying a pre-made one or hiring someone to build it. This is a big draw for many DIYers. You save on labor costs, obviously, and you can often source materials more affordably. For example, many lean-to shed plans utilize common lumber sizes, like 2x4s, which are pretty accessible and not too expensive. This aligns with the idea that you don't need a large budget to give your home a noticeable boost.

Plus, when you build it yourself, you control the budget. You can choose materials that fit what you want to spend, perhaps opting for reclaimed wood for certain parts or finding deals on roofing. It’s a beautiful way to save energy, in a sense, by recycling materials or simply being more mindful of resources. This makes it a very appealing option for those looking for cheap shed plans that still deliver quality and durability.

Personalization and Style

When you build your own shed, you get to make all the choices. This means the size, the look, the color, and even the type of door or windows are entirely up to you. DIY projects are a great way to personalize your home, and a lean-to shed is no exception. You can match it to your home's existing style, or give it a unique flair that expresses your own taste. It’s a chance to really make something your own, to be honest.

Whether you want a shed that blends in seamlessly or one that stands out a little, you have that freedom. You can add shelves, hooks, or even a workbench inside, making it perfectly suited for your specific needs. This level of customization just isn't possible with off-the-shelf options, giving your space a boost that feels truly yours. It's a pretty extraordinary way to spend time, creating something so useful and personal.

Getting Started with Your Lean-To Shed Project

Taking on a DIY project, especially one that involves building a structure, can feel a bit big at first. But with the right approach, it's totally manageable. The key is good planning and knowing what steps come next. Many DIY enthusiasts find that the preparation part is almost as important as the building itself. So, let’s talk about getting ready, you know, for your build.

Choosing the Right DIY Lean-To Shed Plans

The first big step is picking out the right set of plans. There are so many options out there for DIY lean-to shed plans, ranging from very simple designs for beginners to more complex ones for experienced builders. You'll want to find plans that match your skill level and the specific needs you have for the shed. Do you need a small lean-to shed for firewood, or something bigger for a riding mower? That's a pretty important question to ask yourself.

Look for plans that include clear diagrams, a materials list, and step-by-step instructions. Some plans even offer cut lists, which can save you a lot of time and reduce waste. Remember, sites like diyprojects.com offer thousands of free DIY projects, and many include detailed blueprints. It’s time to learn some fantastic new ideas, and choosing good plans is where that journey really begins. A good plan makes all the difference, really.

Essential Tools and Materials

Once you have your plans, you'll need to gather your tools and materials. Most lean-to sheds can be built with common carpentry tools you might already have, like a circular saw, drill, tape measure, level, and hammer. For materials, you'll typically need lumber (often 2x4s for framing, as mentioned in many DIY 2x4 projects), plywood or OSB for siding and roofing, roofing material (shingles or metal), and fasteners like screws and nails. Don't forget proper safety gear, too, like gloves and eye protection; that's very important.

Make sure to check your plans for the exact quantities and types of materials needed. Buying a little extra is often a good idea, just in case of mistakes or future repairs. This preparation ensures you won't have to stop mid-project to run to the hardware store. Having everything ready to go before you start cutting makes the whole process smoother, almost like magic.

Site Preparation is Key

Before you start building, you need to prepare the site where your shed will stand. This involves clearing the area of any debris, leveling the ground, and ensuring proper drainage. A level foundation is absolutely critical for a sturdy and long-lasting shed. If the ground isn't level, your shed could twist or settle unevenly over time, which you definitely want to avoid. You might need to dig out some soil or add gravel to create a stable base, you know?

Also, consider how the shed will attach to your existing structure. You'll need to make sure the wall you're leaning against is sound and can support the added weight. Proper site preparation sets the stage for a successful build and helps prevent problems down the road. It’s a small step that delivers big results in terms of structural integrity, honestly.

Step-by-Step Building Basics

With your plans in hand and your site ready, it's time to start putting things together. Building a lean-to shed involves a series of logical steps, and taking your time with each one will lead to a better outcome. It's not about rushing; it's about being precise and enjoying the process. This is where those easy DIYs really come to life, allowing you to create something functional and beautiful.

Framing the Structure

The frame is the skeleton of your shed, giving it shape and strength. You'll typically start by building the base frame, then attaching the wall studs. For a lean-to, one side of the frame will be shorter than the other to create the sloped roof, which is a pretty distinct feature. You’ll be cutting and assembling pieces of lumber, often following the exact measurements from your DIY lean to shed plans. This is where those DIY 2x4 projects really shine, as much of the framing uses standard lumber.

Ensuring that your frame is square and plumb is incredibly important at this stage. Use a level and a speed square frequently to check your work. Small errors here can compound later, making it harder to fit siding and roofing. Take your time, measure twice, and cut once, as the old saying goes. It's a fundamental part of any home improvement project, really.

Adding the Roof and Siding

Once the frame is up, you'll move on to the roof and siding. The roof typically involves attaching rafters to the top of your frame, then covering them with plywood or OSB sheathing. After that, you'll add a weather barrier and your chosen roofing material, whether that's shingles, metal panels, or something else. The slope of the lean-to roof is designed to shed water effectively, which is a pretty crucial aspect for protecting your stored items.

For the siding, you can use various materials like plywood, T1-11, or even reclaimed wood for a rustic look. Cut the panels to fit your frame and attach them securely. This step not only protects the contents of your shed from the elements but also gives it its finished appearance. It's a great opportunity to express your style, too, in a very visible way.

Finishing Touches and Maintenance

With the main structure complete, it’s time for the finishing touches. This includes installing a door, and possibly windows if your plans include them. You might also want to add trim around the edges for a cleaner look. Painting or staining the shed will protect the wood from weather and can dramatically enhance its visual appeal. This is where your shed truly becomes a part of your home's outdoor aesthetic, you know?

Regular maintenance will keep your lean-to shed in good shape for years to come. Check the roof for leaks, inspect the siding for any damage, and keep an eye on the foundation. A little bit of upkeep goes a long way in preserving your hard work. This whole process, from planning to finishing, can be an extraordinary way to spend time with family and friends, creating something lasting together. Learn more about outdoor structures on our site, and check out this page for more storage ideas.

Common Questions About DIY Lean-To Sheds

People often have a few questions when they start thinking about building their own lean-to shed. Here are some common ones that come up, just to give you a bit more clarity, you know?

How much does it cost to build a lean-to shed?

The cost can really change depending on the size of the shed, the materials you pick, and how much work you do yourself. Generally, building it yourself saves a lot on labor. You might spend anywhere from a few hundred dollars for a small, basic shed using common materials like 2x4s and plywood, up to a thousand or more for a larger, more custom design with fancier siding or roofing. It’s pretty much about what you choose to put into it, honestly.

Do I need a permit to build a lean-to shed?

This is a question you absolutely need to check with your local building department. Rules vary quite a bit from place to place. Some areas allow small sheds under a certain size (like 100 or 120 square feet) without a permit, while others require one for almost any new structure. It's very important to know this upfront to avoid any issues later on. So, always check with your local authorities before you start any digging or building.

What are the best materials for a DIY lean-to shed?

For the frame, pressure-treated lumber is often a good choice, especially for anything touching the ground, as it resists rot and insects. For siding, plywood or OSB with a weather-resistant finish is common and affordable. Roofing materials like asphalt shingles or metal panels are popular because they are durable and protect well against the elements. The "best" materials really depend on your budget, the look you want, and the weather conditions in your area. You want something that will last, basically.

Detail Author:

- Name : Emmanuelle Altenwerth

- Username : mclaughlin.saige

- Email : deonte60@cronin.com

- Birthdate : 2000-03-25

- Address : 2632 Schoen Forge South Adeliatown, SD 82168

- Phone : (870) 443-1315

- Company : Haley, Berge and Reichert

- Job : Personal Home Care Aide

- Bio : Voluptatem velit ratione accusantium corporis nemo. Eum earum nostrum sed enim eum suscipit ab. Eius aut rerum explicabo corporis.

Socials

linkedin:

- url : https://linkedin.com/in/luella_leannon

- username : luella_leannon

- bio : Dolorem at ut quia exercitationem.

- followers : 6215

- following : 1864

tiktok:

- url : https://tiktok.com/@luella.leannon

- username : luella.leannon

- bio : Omnis error occaecati neque impedit. Fugit velit id quisquam sint et.

- followers : 3212

- following : 2790

twitter:

- url : https://twitter.com/leannonl

- username : leannonl

- bio : Harum maiores rerum sunt saepe rem. Debitis enim occaecati nulla ad. Vel quis hic dolorem molestiae vel aut iste laborum.

- followers : 4054

- following : 1817